Overview

One of the United States' largest managed print services providers, FlexTG(R), generating over $500 million in revenue, faced significant operational challenges with its manual, unpredictable service processes. Despite having thousands of IoT printer devices deployed at customer sites generating millions of logs, the company could not leverage this data due to legacy ERP systems and a lack of proper documentation.

The company needed a solution that could unlock the potential of its IoT infrastructure while working alongside its existing systems.

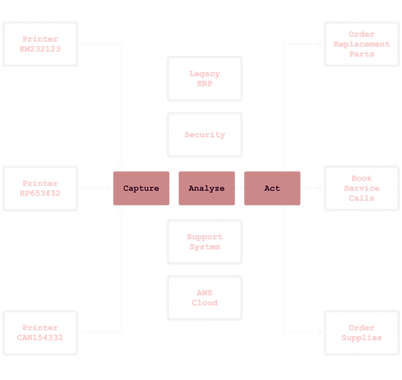

Our challenges were twofold: first, to integrate with their undocumented legacy ERP system, which lacked APIs, and second, to build a scalable platform that could collect, analyze, and monetize the massive amounts of unstructured printer log data generated across their customer base.

Services

For FlexTG®, we delivered a transformative digital solution that shattered legacy limitations and unlocked substantial operational value. We began by decoding a complex ERP system that lacked modern APIs, leveraging our technical expertise to extract and integrate vital data into a cutting-edge digital framework. This breakthrough enabled us to build a robust IoT data platform that ingests, curates, and enriches millions of printer logs in real time—turning raw data into actionable insights for proactive support and strategic decision-making.

Utilizing a cloud-first architecture on Amazon AWS, we developed a highly scalable, resilient infrastructure that enhances efficiency and drives innovation. Additionally, we engineered an intelligent supply automation engine that streamlines procurement and fulfillment processes, ensuring timely delivery of essential supplies. Together, these services not only reduce costs and boost operational efficiency but also set a new standard in customer service—delivering measurable ROI and a competitive edge in the managed printing industry.

Building & Scaling on Cloud

We designed and developed a cloud-first platform on Amazon AWS that was able to generate machine intelligence in real-time and linearly scale to support the massive volumes. The platform architecture was designed to be fully distributed to scale up and down on-demand.

Impact

The platform is the foundation to monetize IoT and enable digital transformation. The client is able to automate processes and improve customer experiences - which were not possible until now.

We're excited to see it evolve and allow our clients to use the power of digital and data to reduce costs, improve efficiencies, and grow their businesses.

50%

Reduction in service time

30%

Cost savings

70%

Fewer printer downtime

40%

Increase in operational efficiency

More Stories